Why Are Lead Auditor Services in Israel Relevant for You?

It is well-known that companies from the medical device and pharmaceutical industries in Israel and abroad must follow strict regulatory requirements. Part of the effort that should be given is finding the appropriate lead auditor in Israel to authorize, qualify, and approve your external service providers and suppliers.

In addition, all companies are using third-party services as part of their routine operations.

These third-party services in Israeli companies can be used for a variety of activities such as:

- Development

- Raw materials and APIs

- Device components

- Manufacturing

- Assembly

- Packaging

- Sterilization

- Storage

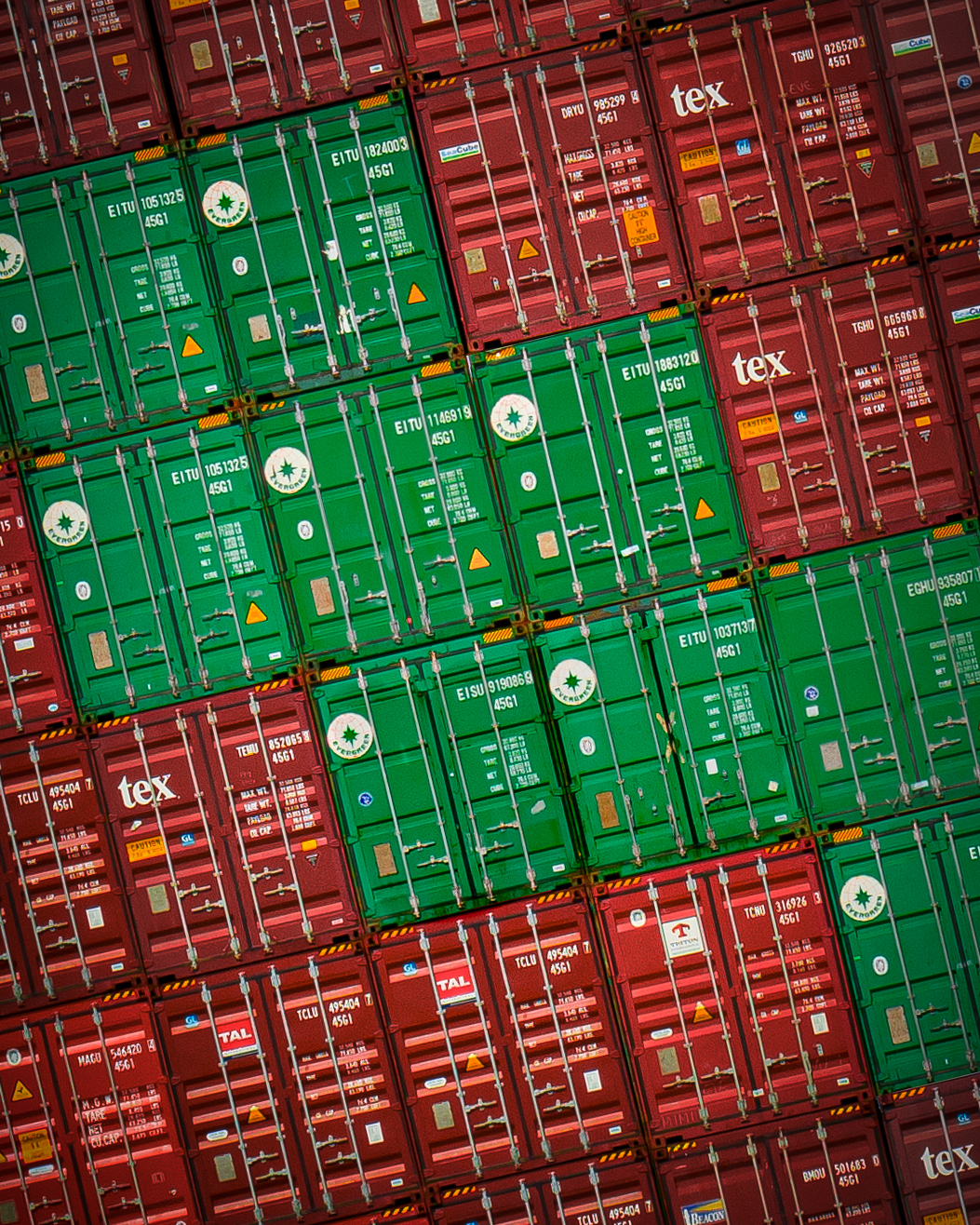

- Transportation

- Laboratory testing

- Stability studies

These kinds of services can be given from local suppliers or global ones, and both need to be audited for their QMS, GMP, and regulatory requirements compliance.

Global Audits and Quality Inspections in the Pharmaceutical and Medical Device Industries

The Bio-Med industry has become massively global in the past two decades. It means you have many business partners, suppliers, service providers, and contract manufacturers in many countries, and you have to be sure they maintain their quality-related obligations and duties.

For example, A typical company may have an API supplier from Israel, a contract manufacturer from India, and a testing laboratory from Germany. In order to comply with the ISO 13485/GMP/FDA/EMA regulations, we need to have worldwide auditing and inspection capabilities that will enable us to meet the regulatory requirements and avoid observations in the regulatory body’s inspection.

All of these suppliers need to have a third-party audit periodically, and in most cases, you need to hire an external lead auditor service to do it right.

Quality System Audits and Inspection Areas

As part of the quality management system, such as the ISO 13485, MDSAP, and the GMP requirements, you need control over many critical points that may affect your manufacturing and assembly processes as well as your final product safety and quality.

The main pillars of the quality management system in medical device, pharmaceutical, and even digital health companies are:

| Audited area | Audit purpose |

| Facility & Equipment | To ensure your supplier’s facility and equipment meet the design standards, are operated and maintained correctly, and are in a validated state |

| Production & Assembly | Ensure your product/device assembly and manufacturing processes are controlled, and performed based on the approved working instructions and that all processes from raw material/components receiving until final product storage are documented, controlled appropriately, and performed by qualified personnel |

| Quality system | To ensure your supplier’s QMS documents were written and approved based on the relevant and current regulatory requirements, the quality management system and good practices are implemented correctly, and there are no gaps between what is written and what is actually done on the production floor |

| Quality Control | To ensure there is proper quality control and testing over components, materials, manufacturing, in-process, printed material, packaging, and the final product before release, it is being done based on well-written SOPs and instructions |

| Self-inspection | Ensure all your company’s departments constantly follow the procedures, good practices, and quality aspects routinely |

| Return and complaints | To ensure all post-marketing procedures are implemented, product returns and customer complaints are being documented and managed in a controlled manner for continuous improvement |

| Organisation & personnel | To ensure the company’s organizational chart supports product quality and safety reduces the potential risks and conflict of interest, and assures that all personnel have the education, experience, training, and qualification to do their jobs appropriately |

| Outsourced operation | To assure the company’s suppliers, contractors, and service providers were chosen carefully and can deliver high-quality and reliable services/safe products, that they were qualified based on a questionnaire, that a quality agreement was signed, that they maintain a quality management system, and that they were inspected before approval and periodically |

| Documentation | That all the processes related to the product, from supplier approval until final product distribution, are adequately documented, using controlled documents, policies, SOPs, and protocols, and that all the required QMS, ISMS, and GMP documents were written and approved |

Outsourced operations are considered very critical and risky areas in the Bio-Med industry, and accordingly, a particular emphasis is given to outsourced operations

You can have a well-organized and effective quality management system. Still, you cannot guarantee your critical supplier does the same, and that is why you need to hire an external auditor service.

Second and Third-Party Audits in Israel

The regulation expects the company to have exceptional control over its suppliers and conduct self-inspections internally as well. Second and third-party audits are very common practices in the pharma and medical device industries, and many medical and pharmaceutical third parties are located in Israel and should be audited accordingly.

Regulatory agencies and business partners will audit you, and on the other hand, you need to audit your partners, service providers, and suppliers. It is your responsibility to work with qualified third parties.

You need to report to the regulatory authorities in case of deviation, customer complaint, or recall. You have to assure your suppliers and contract manufacturers maintain an effective quality system and follow what has been agreed upon and signed as part of the quality agreement.

Common Audits and Inspections in the Medical and Pharma companies based in Israel

Here are some audit types that should be performed in pharma and medical device companies based in Israel:

- Raw materials suppliers’ audits

- Medical components and parts audits

- Laboratory services audits

- Service providers’ audits

- Equipment manufacturers’ audits

- Contract manufacturers’ audits

- Sterilization service provider audits

Lead Auditor Services in Israel

There are thousands of medical devices, pharmaceuticals, and digital health companies, service providers, and contractors in Israel. Most of these companies are operated globally and need to be audited and inspected periodically.

I’m a certified lead auditor based in Israel, work worldwide, and internationally registered auditor in the IRCA. There are many advantages to using local Israeli-certified lead auditor services to assure your supplier can be fully trusted and follow the regulatory requirements.

I was recognized and accredited by the global NSF, IRCA, and CQI, with a proven track record of many first and second-party audits worldwide.

With more than 20 years of experience in the pharma, medical device, and digital health industries, I offer my clients my lead auditor capabilities in Israel and globally according to various audit regulations such as:

- ISO 13485

- FDA 21 CFR part 11

- Eu. GMP

- US GMP 21 CFR210/211

- EU GDP Guide

- FDA 21 CFR 820

- Vefification & Validation

- Sterilization

- GDP

- MDSAP

- ISO 27001

- ISO 27799

- GDPR

- HIPAA

- And many more

Due diligence or regulatory body inspections are a significant milestone for all Medical devices, E-Health, and pharmaceuticals. To ensure you choose the best partners along the way to meet the regulatory requirements, you need auditing capabilities and proper guidance.

I’m offering my lead auditor services and consulting for Bio-Med clients for second-party and third-party audits in Israel and worldwide.